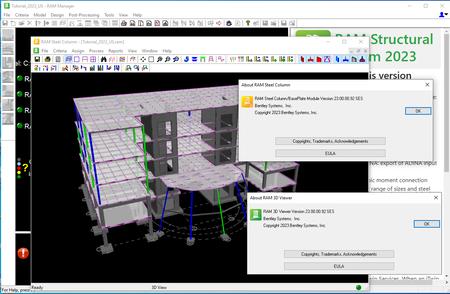

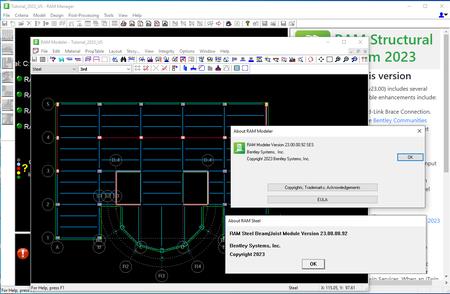

RAM Structural System CONNECT Edition 2023 (23.00.00.92)

- ПРОГРАММЫ

- 2-05-2023, 16:51

- 158

- 0

- voska89

Free Download RAM Structural System CONNECT Edition 2023 (23.00.00.92) | 2.6 Gb

Product:RAM Structural System

Version:CONNECT Edition 2023 (23.00.00.92)

Supported Architectures:x64

Website Home Page :www.bentley.com

Languages Supported:english

System Requirements:Windows *

Size:2.6 Gb

The Structural Products development team is pleased to announce the availability of RAM Structural System CONNECT Edition 2023 (23.00.00.92). This software provides you a complete solution for analysis, design, drafting, and documentation for steel and concrete buildings, foundations, and even individual structural components; all in compliance with your local building codes.

RAM Structural System 2023 (23.00) Release Notes - Release Date: March 30, 2023

Bentley program versions are now identified by the year of release. This release is RAM Structural System 2023. Internally, the version number is v23.00.00.

For details on these new features and enhancements, refer to the manual .pdf files available from the Help menu in each module or from the RAM Structural System Manuals directory.

Yield-Link Brace Connection

Working closely with Simpson Strong-Tie, the requirements for the selection of their Yield-Link Brace Connection and the design of braced frames using that connection have been extensively implemented. These connections can easily be assigned to braces in RAM Frame, and the frames and connections analyzed and designed for wind and seismic forces.

Move Line Loads and Point Loads

A Move option has been added to the Layout - Loads - Line Loads and Layout - Loads - Point Loads commands in the Modeler, allowing Point loads and the ends of Line loads to be moved to a new location. Previously those loads needed to be deleted and then remodeled if it was necessary to relocate them.

Improved Snap Point Behavior

When modeling, the program determines and provides Snap Points, that is, points at which the cursor can snap, allowing members, decks, loads, etc., to be placed at those points. A thorough review of the Snap Point creation process resulted in refinements and improvements to make the list of Snap Points more responsive to the additions, deletions, and changes made to the model.

Mesh Property Warnings

Some conditions are problematic for the automatic mesh generator when generating the mesh for semirigid or two-way deck diaphragms in RAM Frame that result in an inability to assign properties to those mesh elements. During the Meshing Process, warnings are given when those conditions occur. Previously the warning stated that the condition existed but did not identify the location of the bad elements. Now the warning lists the coordinates of the centroid of the mesh element so that they can more easily be located. Their occurrence generally indicates an error in modeling, for example a deck polygon whose edge is very nearly but not exactly coincidental with a wall or frame beam. The necessary corrections should be made to the model.

Interoperability with ADINA

Bentley's ADINA is powerful finite element software for the analysis of nonlinear structures involving geometric, material, and load nonlinearities; large deformations; and contact conditions. The RAM Structural System now has the ability to export a model and create an ADINA input file. To create the file, merely select the Generate ADINA Input file option in the Process - Analyze command in RAM Frame. This is a Technology Preview feature; work is ongoing to add capabilities to this feature.

Out-of-Plane Shear Failure of Walls in Tension

When a wall is under axial tension, the program simply assumes that the out-of-plane shear capacity, fVn, is 0.0. This is consistent with ACI 318-11 11.2.1.3. By the nature of the analysis in RAM Frame, in which a very small value of out-of-plane stiffness must be used to avoid an analytical instability (division by 0), the analysis gives very small values of out-of-plane shear, Vu; this caused the wall to be flagged as failing (because the wall was in tension so the out-of-plane shear capacity, fVn, was 0.0, but the shear from the analysis, Vu, was some small non-zero value). The program has now been modified so that there is a tolerance on that check, it now allows a small incidental value of shear without flagging the wall as failing.

Eurocode Concrete Column Slenderness

Clause 5.8.3.1(1) of EN 1992-1-1:2004+A1:2014 allows second-order effects to be ignored if the slenderness of the column is less than the slenderness limit, llim., given by Eq. (5.13N). For braced members in which the first-order moments are predominantly due to the minimum eccentricity, the coefficient C in that equation is to be taken as 0.7. Previously the program set C to 0.7 if the moment at either end was predominantly due to the minimum eccentricity; that may have been very conservative. Now the program only sets C to 0.7 if the moments at both ends are predominantly due to the minimum eccentricity.

Updated DuraFuse Table

The DuraFuse table of permitted column and beam sizes and grade has been updated. The lists of acceptable SMF and MF wide-flange column sizes have been updated for depth and section limits per the highly ductile and moderately ductile requirements, respectively, and expanded to include acceptable wide-flange sizes for steel Grades 50, 55, 60, 65, and 70 ksi. The lists of acceptable SMF and MF HSS column sizes have been updated for depth and section limits per the highly ductile and moderately ductile requirements, respectively, and are now limited to steel Grade 50 ksi. The lists of acceptable SMF and SM wide-flange beam sizes for steel Grade 50 ksi have been updated for depth, weight, and section limits per the highly ductile and moderately ductile requirements, respectively.

Fabsec FBEAM Fire Data

In the UK, Fabsec's FBEAM program for the design of Fabsec beams has the ability to import a RAM Structural System model and design the steel beams as Fabsec beams, then to export the designs back to RAM Structural System where they can be displayed. This interoperability has been enhanced to include the fire engineering data that is produced by FIREBEAM®, an add-on to the FBEAM program, including the fire-proofing product, the thickness, and the fire rating period. When exported to the RAM Structural System this information can be viewed in the Layout - Beam - Show command in the Modeler, and displayed in Steel Beam, using the View - Show Fabsec Fire Data command, and in the 3D Viewer.

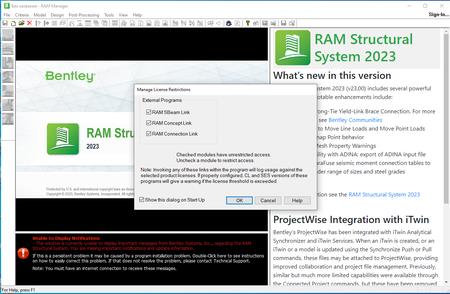

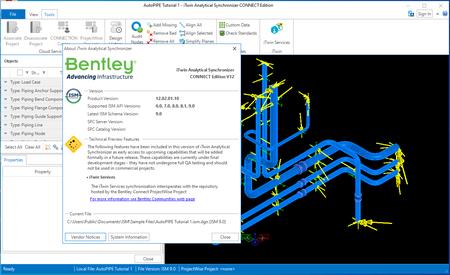

ProjectWise Integration with iTwin

Bentley's ProjectWise has been integrated with iTwin Analytical Synchronizer and iTwin Services. When an iTwin is created, or an iTwin or a model is updated using the Synchronize Push or Pull commands, these files may be attached to ProjectWise. ProjectWise Design Integration improves collaboration within organizations through the use of ProjectWise 365 projects and various new ProjectWise Cloud Services. By associating new or existing projects with ProjectWise 365 projects in the cloud, you can leverage ProjectWise 365 Services including ProjectWise Web, Deliverables Management, and Project Insights. Previously, similar but much more limited capabilities were available through the Connected Project commands, but these have been removed from the program and replaced with the more powerful ProjectWise capabilities. You must install ProjectWise v10.00.03 or later in order to enable this capability.

iTwin Design Review

New data is now available for use and display in Bentley's iTwin Design Review, including Utilization (Strength Demand/Capacity) Ratio of beams and columns, and Critical Deflection Interaction (Actual/Allowable) of beams.

Some program errors have been corrected for this version. Corrections made to graphics, reports, Modeler functions, program crashes, etc., that were considered minor are not listed here. The noteworthy error corrections are listed here in order to notify you that they have been corrected or to assist you in determining the impact of those errors on previous designs. These errors were generally obscure and uncommon, affecting only a very small percentage of models, or had no impact on the results. The errors, when they occurred, were generally quite obvious. However, if there is any question, it may be advisable to reanalyze previous models to determine the impact, if any. In each case the error only occurred for the precise conditions indicated. Those errors that may have resulted in un-conservative designs are shown with an asterisk. We know these errors are disruptive, we apologize for any inconvenience this may cause.

iTwin

iTWIN SYNCHRONIZATION: Some errors in the iTwin Push and Pull processes prevented iTwins from successfully being created or updated from models or prevented models from successfully being created from iTwins. Most notably, the commands frequently crashed and there were errors associated with sloping framing, columns may not have been imported or exported with the correct column height

Effect: Unsatisfactory or no interoperation between iTwin and the RAM Structural System model.

DXF

COLUMN SCHEDULE: If columns in a stack did not have precisely the same coordinates they were included in the Column Schedule with separate Marks rather than being scheduled as part of the same column line.

Effect: Columns with slightly different coordinates that were intended to be in the same column stack were scheduled as separate column stacks.

Modeler

CANTILEVER OVER SLOPING COLUMN: If an attempt was made to add a cantilever to a beam supported by a sloping column an error message was erroneously displayed indicating that the cantilever crossed another member.

Effect: A cantilever couldn't be added to a beam supported by a sloping column.

SNOW DRIFT LOADS: The DataCheck performs a check to determine if the way the Snow Drift loads are modeled would result in a negative snow load value being applied. This check was sometimes giving erroneous warnings, particularly when the calculated load value at a Snow drift load polygon vertex would result in a load magnitude of 0.00.

Effect: Some messages were erroneous given indicating that a snow load would generate negative snow loads.

DATACHECK (TECHNOLOGY PREVIEW): When performing the check to determine if Beams or Walls were slightly skewed with respect to either the X- or Y-axis, the program erroneously reported all skewed beams, not merely those within the specified tolerance.

Effect: All skewed beams were reported as slightly skewed, making it difficult to investigate those that truly were only slightly skewed.

Framing Tables

CORRUPT OPENING EDGES FOLLOWING BEAM, COLUMN, OR WALL MOVE: In very specific cases, a Move command may have caused a slab opening edge to have the incorrect orientation (right-to-left instead of left-to-right). This corruption of the opening edge was not apparent, the graphics were correct, but in rare cases it caused unpredictable results in determining loads on beams at the edge of an opening.

Effect: In very rare cases, a beam, wall, or column Move next to a slab opening caused incorrect loads. Note: existing models with this corruption are automatically corrected when the model is run in this version.

LINE LOAD SLIGHTLY OFFSET FROM WALL: In rare cases, a line load parallel to and slightly offset from a wall caused the error "Beam Loop Intersection not Found." The error did not occur for line loads perfectly aligned with the wall, and it didn't occur for beams.

Effect: Several modules including Steel Beam, Steel Column, and Concrete Analysis crashed when a line load was slightly offset from a wall.

Steel Beam

EXPORT TO RAM SBEAM: The command to export the beam design data to RAM SBeam, Process - Export To SBeam, did not function properly, RAM SBeam would not launch.

Effect: Unable to launch RAM SBeam from RAM Structural System.

UNBRACED LENGTH: In rare cases the program failed to recognize the presence of a beam to provide lateral bracing when determining the unbraced length.

Effect: An unbraced length greater than necessary may have been used to design the beam.

STEEL JOISTS NET TOTAL DEFLECTION: The SJI specification does not require that joists be designed for a limit on net total deflection, but if the user assigned a limit to that deflection the program correctly selected steel joists that conformed to that limit. However, the Standard Joist Selection report for those joists displayed some erroneous text when comparing the actual Net Total deflection with the user-specified limit, and the Ratio was incorrect. The reported Net Total deflection correctly considered the beneficial effect of camber, but the text comparing that deflection to the limit failed to consider camber.

Effect: Report error only, the actual design was correct.

Concrete Analysis

ACI LIMIT ON SQUARE ROOT OF SPECIFIED COMPRESSIVE STRENGTH OF CONCRETE USED TO CALCULATE TORSION:* ACI 318-19 Sec. 22.7.2.1 (and previous codes) states a limit of 100 psi for the square root of specified compressive strength of concrete used to calculate Tth and Tcr. This limit was not applied by the program.

Effect: When f'c was greater than 10 ksi, incorrect values of Tth and Tcr were used in torsion design requirements of ACI 318-19 Sec. 22.7.

ACI 318 MAGNIFICATION FACTOR δs FOR SWAY FRAME COLUMNS*: In lieu of a P-Delta analysis, ACI 318 permits a 1st-order analysis with the sway moments factored by a magnification factor, δs, given by Eq. (6.6.4.6.2b). In that equation, the sum of all factored gravity loads in the story (SPu) and the sum of the critical buckling loads for all columns in the story (SPc) are required. In the program there was an option to apply the magnification factor to the sway frame moments. However, the implementation was incorrect; it used the individual column's Pu and Pc in calculating that column's magnification factor, rather than using the sums of Pu and Pc for the entire story. The option "Apply Magnification Factor, ds to sway frame columns" in the Criteria - Analysis command has been removed. To account for P-Delta, the option in the Criteria - General command in RAM Frame to include P-Delta must be selected.

Effect: The moment magnification factor calculated by the program when the option "Apply Magnification Factor, ds to sway frame columns" may have been incorrect, resulting in incorrect moments being used for design.

Concrete Beam

ACI 318 DIMENSIONAL LIMITS IN SMF BEAMS*: ACI 318-19 Sec. 18.6.2.1 © was not considered in the design. Instead, an earlier code requirement (ACI 318-02 Sec 21.3.1.4 (b)) was considered.

Effect: No warning was given for beams with width greater than permitted per ACI 318-19 Sec 18.6.2.1 ©.

ACI 318 CROSS-SECTIONAL LIMIT FOR TORSION*: ACI 318-14 Sec. 22.7.7.1(a) limits the cross-sectional dimensions of beams for torsion. The program used Vu instead of Vc to calculate that limit in the right-hand term in Eq 22.7.7.1a.

Effect: No warning was given if the cross-section size was less than required per ACI 318-19 22.7.7.1(a).

ACI 318 MAXIMUM SPACING OF SHEAR LEGS ACROSS THE BEAM WIDTH: ACI 318-19 Table 9.7.6.2.2 provides a limit for the maximum spacing of legs and shear reinforcement. While the maximum shear reinforcement spacing is correctly only checked for cases where shear reinforcement is required, the maximum spacing of legs was checked in all cases, even if shear reinforcement was not required.

Effect: The waning "Maximum spacing of legs across the Beam width exceeded" may have appeared in cases where shear reinforcement was not required.

Concrete Column

MAXIMUM TRANSVERSE REINFORCEMENT SPACING LESS THAN THE USER-SPECIFIED MINIMUM*: If the user specified a Minimum transverse reinforcement spacing that was greater than the Code-required maximum per ACI 318-19 Sec 10.7.6.5.2 the program selected reinforcement that satisfied the user-specified Minimum but failed to give a design error indicating that the reinforcement didn't conform to the Maximum spacing requirements.

Effect: In the case of conflicting criteria, the program failed to give a warning that ACI 318-19 Sec. 10.7.6.5.2 was not satisfied.

Concrete Wall

CONCRETE WALLS WITH DIFFERENT MATERIALS*: When two or more walls with different material properties were part of the same Wall Design Group, the program only considered the assigned material of the first wall.

Effect: Walls with different fy or f'c within the same Wall Design Group may have been designed incorrectly using fy or f'c of the first wall in the Wall Design Group rather than the values of fy or f'c assigned to the wall by the user.

COUPLING BEAM SHEAR CAPACITY TO ENSURE FLEXURAL FAILURE*: ACI 318-19 Sec. 18.6.5.2 and previous ACI codes do not allow consideration of the contribution of the concrete strength, Vc, in the determination of the shear strength when Ve is greater than one-half of the maximum required shear strength and the axial compression force Pu is less than Ag*f'c/20. The program did not consider this limit during the design.

Effect: The coupling beam shear capacity may have been over-stated when the conditions of ACI 318-19, Sec. 18.6.5.2 occurred.

ACI 318 LIMITS ON MOMENT STRENGTHS IN COUPLING BEAMS*: ACI 318-19 Sec 18.6.3.2 and previous codes set minimum limits for positive and negative moment strengths. These limits were not checked.

Effect: The program did not consider the limits per Sec. 18.6.3.2 in the design and verification of longitudinal reinforcement.

ACI 318 MAXIMUM SPACING OF TRANSVERSE REINFORCEMENT IN BOUNDARY ELEMENTS: Boundary element ties are governed by ACI 318-14 and ACI 318-19 Sec. 18.10.6.4(e), which requires Sec. 18.7.5.2(a) through (d) and Sec. 18.7.5.3 be satisfied, with some exceptions. Sec. 18.7.5.3(a) requires that the transverse reinforcement spacing limit be one-quarter of the minimum member dimension, but Sec. 18.10.6.4(e) permits that limit to be increased to one-third of the least dimension of the boundary element. The program was imposing the limit based on one-quarter of the minimum member dimension. Similarly, for ACI 318-11 the program was imposing the more stringent spacing of Sec. 21.6.4.3(a) rather than the less stringent spacing permitted by Sec. 21.8.6.4©.

Effect: The program may have imposed a closer spacing on the transverse reinforcement than required by Sec. 18.10.6.4(e) (or of Sec21.8.6.4© for ACI 318-11).

INCORRECT ACI CLAUSE REFERENCE: In View Update and on the design reports the section referring to transverse reinforcement requirements when boundary elements are not required (Sec 18.10.6.5(b) in ACI 318-19 and 21.9.6.5(a) in ACI 318-11) were incorrectly reported as Sec. 18.10.6.5(a) in ACI 318-19 and Sec. 21.6.5.7(a) in ACI 318-11.

Effect: Report error only, the wrong section references were listed. The designs were based on the correct sections.

ACI 318-11 MAXIMUM SPACING OF TRANSVERSE REINFORCING BARS IN WALL BOUNDARIES*: When special boundary elements are not required by ACI 318-11 Sec. 21.9.6.2 or Sec. 21.9.6.3, the requirements of Sec. 21.9.6.5 must be satisfied. When checking the requirements of Sec. 21.9.6.5(a) the program erroneously used the transverse reinforcement ratio rather than the longitudinal reinforcement ratio.

Effect: Incorrect value of reinforcement ratio was used to determine the requirements of ACI 318-11 Sec. 21.9.6.5(a).

MAXIMUM SPACING OF TRANSVERSE REINFORCEMENT AT WALL BOUNDARY: The program applied the requirements of ACI 318-11 Sec. 21.9.6.5(a) (and earlier codes) for structures in Seismic Design Categories A and B even though that section does not apply to those Seismic Design Categories.

Effect: The warning message: "Max Vert Spacing Limit per 21.9.6.5a at Reinforcing Zone is exceeded." may have erroneously appeared for Seismic Design Categories A and B.

ACI 318-19 MINIMUM VERTICAL REINFORCING IN CONCRETE WALLS: The minimum reinforcing ratio allowed for concrete walls in the program was the minimum value defined in ACI 318-19 Sec. 11.6.2. However, Section 11.6.1 permits a lower minimum reinforcing ratio when Vu £ 0.5faclsqrt(f'c)Acv.

Effect: The vertical wall reinforcement may have been greater than required.

INCORRECT ACI CODE REFERENCE: When minimum required horizontal reinforcement failed per ACI 318-19 or ACI 318-14 Sec. 11.6.1, the warning message incorrect listed the reference as Sec 14.3.3.

Effect: Report error only, the wrong section was referenced. The designs were based on the correct section.

CRASH: When an attempt was made to assign a bar pattern template to a new model, the Concrete Wall module crashed.

Effect: New models experienced a crash when assigning a bar pattern template.

ACI 318-19 DYNAMIC SHEAR AMPLIFICATION FACTOR (omega_v)*: For a single story wall the program used a dynamic shear amplification factor of 0.9 rather than the value of 1.0 given by Eq. (18.10.3.1.3), potentially resulting in an unconservative design. For walls where ns was greater than 6, the greater value of 1.3 + ns/30 and 1.8 was used rather than the lower value, potentially resulting in a conservative design.

Effect: Incorrect shear amplification factors required by ACI 318-19 Sec.18.10.3.1.3 may have been used in design.

CLEAR BAR COVER LISTED IN WALL PANELS PROPERTIES REPORT: Regardless of the options selected (Code or Use) or the values assigned for Clear Bar Cover in the Criteria - Design Criteria command, the Wall Panel Properties report always listed "Code".

Effect: Report error only. The correct values were used in design, but the report always listed "Code".

ACI 318-19 CONCRETE SHEAR CAPACITY IN WALLS: ACI 318-19 considers the gross area of concrete section to resist shear. However, the program used the effective depth ( 0.8 times the thickness) to calculate the resisting shear area as used in older versions of the ACI code.

Effect: A concrete shear capacity less than the capacity defined by ACI 318-19 Sec. 11.5.4.3 was used for design.

ACI 318 MAXIMUM TRANSVERSE REINFORCEMENT SPACING IN BOUNDARY*: The maximum spacing for transverse reinforcement in boundary elements when these are not required by ACI 318-19 or ACI 318-14 Sections 18.10.6.2 or 18.10.6.3 is governed by ACI 318-19 Sec. 18.10.6.5(b) or by ACI 318-14 Sec. 18.10.6.5(a). Rather than applying those limits, the program used the less stringent spacing limit requirement of ACI 318-11.

Effect: The maximum spacing of transverse reinforcement at wall boundaries may have been greater than that required by ACI 318-19 Sec. 18.10.6.5(b) and ACI 318-14 Sec. 18.10.6.5(a).

CREATION OF PANELS: When a wall type was changed from Tilt-up to Cast-in-place in the Modeler, the program saved the previous Tilt-up wall gap assignment information and may have used that to create separate panels in the cast-in-place wall.

Effect: Cast-in-place walls may have been split unnecessarily into individual panels.

Frame - Analysis

PRESSURE LOADS ON WALLS IN SI UNITS: When pressure loads are defined in SI units in thePropTable - Lateral Loads - Wall Pressure Loadscommand in the Modeler, an internal units conversion error results in very large pressure forces being applied in RAM Frame.

Effect: Extremely large erroneous forces are applied to the walls and analyzed.

DIAPHRAGM SECTION FORCES: The Diaphragm Section Forces report contains two sections: the first section lists discrete points locations and relative distances, and the second section lists force results at those discrete points. Depending on the direction that the section cut was drawn the results either corresponded with the order that the locations were listed or else they were listed in opposite order.

Effect: Report error only. The values were correct but may have been listed in the opposite order of the locations.

Frame - Shear Wall Forces

CHANGE SECTION CUT: Using the Assign - Section Cuts - Change command to modify a section cut caused the program to crash.

Effect: Program crash.

Frame - Steel Standard Provisions

YIELD-LINK AXIAL CAPACITY CHECK: Joint code checks for connections with Yield-Link Moment Connections on Side-A of a joint did not correctly report the overall design as failing even when the report showed a failing ratio for the axial capacity check.

Effect: Report error only. Although joint code checks for connections with Yield-Link Moment Connections were correctly performed, when the axial capacity checks for links on Side-A failed, that was properly reported for that check on the report, but the report did not list the overall design status as failing.

MISSING COMBINATION IN IBC/ASCE STEEL LRFD COMBINATIONS*: When the backspan support of a cantilever beam or a user-specified upward acting load induces negative (upward) forces on a frame member, the program creates Negative Live and Roof, and Snow load cases, indicated in the load combination generator as Ln, Rfn, and Sn, respectively. The AISC LRFD combinations in the templates for IBC 2006, 2009, 2012, 2015, 2018, and 2021 were missing the combination with the negative Roof loads, Rfn, when in combination with the Roof Notional Load acting in the negative global axis direction (i.e., -X-direction or -Y-direction).

Effect: When those LRFD combinations were generated, the combination with notional loads in the positive global axis direction (1.2*D + 1.2*ND + 1.6*Rfn + 1.6*NR) was correctly generated, but the combination with notional loads in the negative global axis direction (1.2*D - 1.2*ND + 1.6*Rfn - 1.6*NR) was not generated. Note that this combination would rarely control, only if the effect of upward acting roof loads were larger than the effects of wind and seismic loads.

Frame - Steel Seismic Provisions

ASD STRONG COLUMN - WEAK BEAM EXCEPTION CHECK*: In the SCWB joint code check for AISC 341-10/16 ASD codes, the Pc calculation did not include alpha-s.

Effect: Joint checks performed according to AISC 341-10/16 ASD may have allowed the Exception of Section E.4a(a) because the program was using an incorrect Pc. The value of Pc was not reduced by the ASD factor, alpha-s equal to 1.5.

COLUMN WEB SPLICE STRENGTH: The required shear strength of column web splices designed according to AISC 341-10/16 may have been incorrect if the sizes of the columns at the splice were different.

Effect: The check for required shear strength of column web splices performed in accordance with Section E3.6g was erroneous if the columns above and below the splice were sized differently. ∑Mpc used the Zx of the column above the splice for the column below the splice.

YIELD-LINK MOMENT CONNECTION - COLUMN FLANGE WIDTH CHECK*: Joint code checks on joints with Yield-Link Moment Connections failing the Column Flange Width check were not flagged as failing.

Effect: Joints with the Yield-Link Moment Connection failing the minimum column flange width requirement were not flagged in the reports as failing.

Foundation

ONE-WAY SHEAR IN SPREAD FOOTINGS*: The Optimization process did not increase the footing thickness when one-way shear strength was less than the required strength. As a result, footings with insufficient depth may have been presented as the design, if one-way shear should have controlled the design. The design report correctly showed that Vu was greater than ϕVn, but the report did not flag that as a design error, and View/Update did not indicate that the footing failed. Although this may have rarely occurred with previous versions of ACI 318, it may have been more prevalent with ACI 318-19 where the shear capacity was reduced.

Effect: Design error when one-way shear should have controlled the design depth.

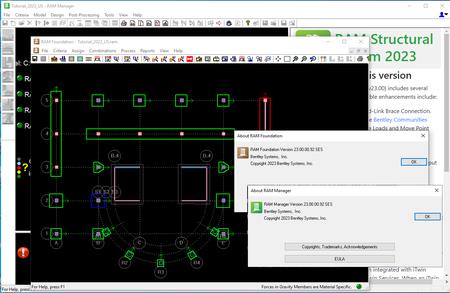

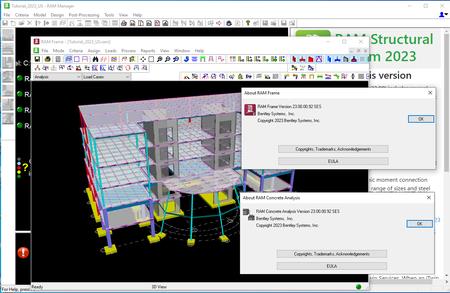

TheRAM Structural Systemis powerful and versatile special purpose software for the analysis and design of building structures. It is useful in the design and analysis of commercial, institutional and industrial buildings. The RAM Structural System includes the following modules: RAM Manager, RAM Modeler, RAM Steel Beam and Column, RAM Frame, RAM Concrete, and RAM Foundation.

RAM Structural System Steel Tutorial

Basic tutorial on inputs for a gravity model for a steel framed building using Bentley's RAM Structural System.

Bentley Systems, Incorporatedis the global leader dedicated to providing architects, engineers, constructors, and owner-operators with comprehensive architecture and engineering software solutions for sustaining infrastructure. Founded in 1984, Bentley has nearly 3,000 colleagues in more than 45 countries, $500 million in annual revenues, and, since 2001, has invested more than $1 billion in research, development, and acquisitions.

Rapidgator

http://peeplink.in/dc91c378905f

Uploadgig

ye9it.SETUP.part1.rar

ye9it.SETUP.part2.rar

NitroFlare

ye9it.SETUP.part1.rar

ye9it.SETUP.part2.rar

Links are Interchangeable - Single Extraction